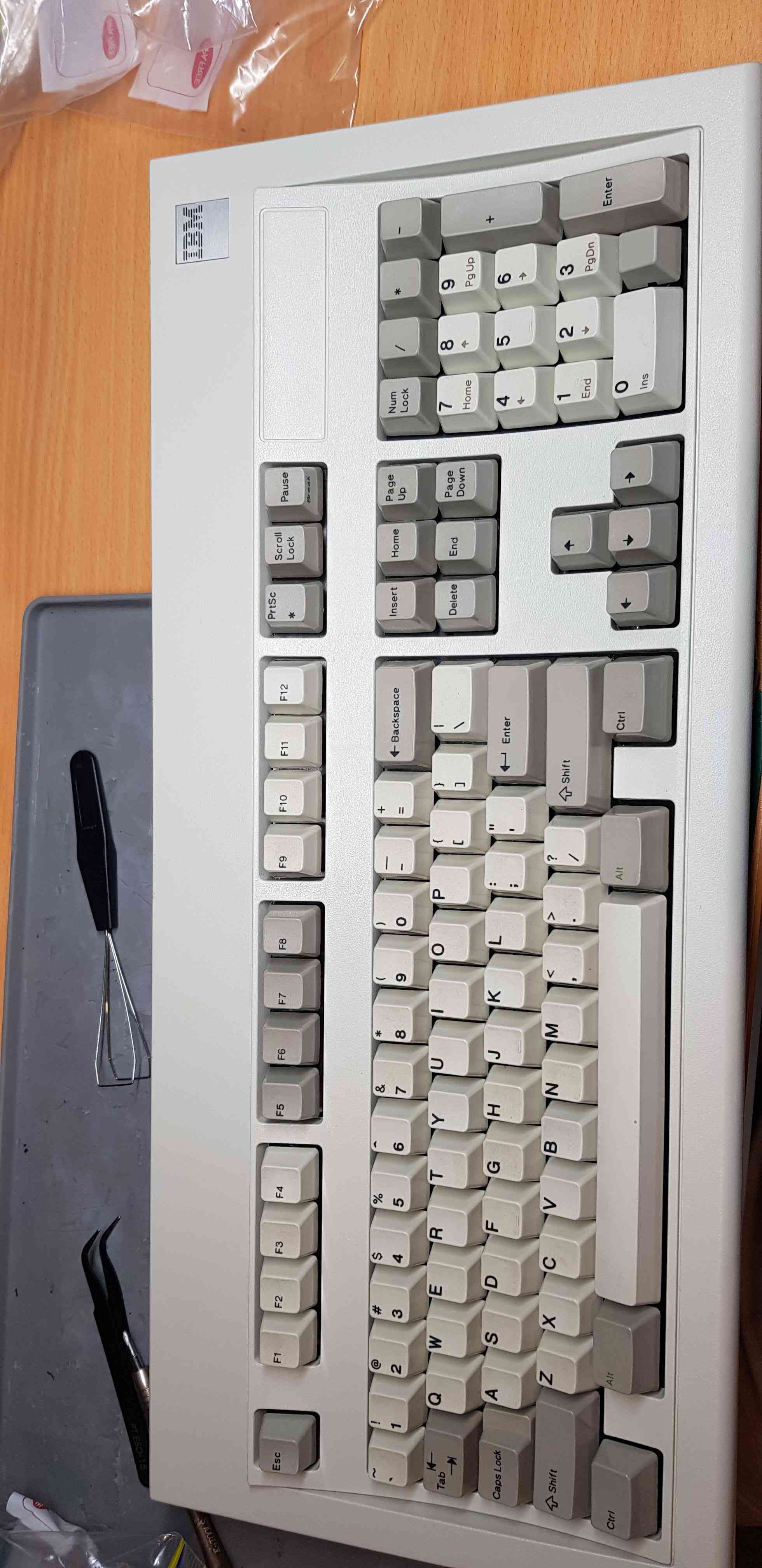

IBM Model M restoration

17/2/2022

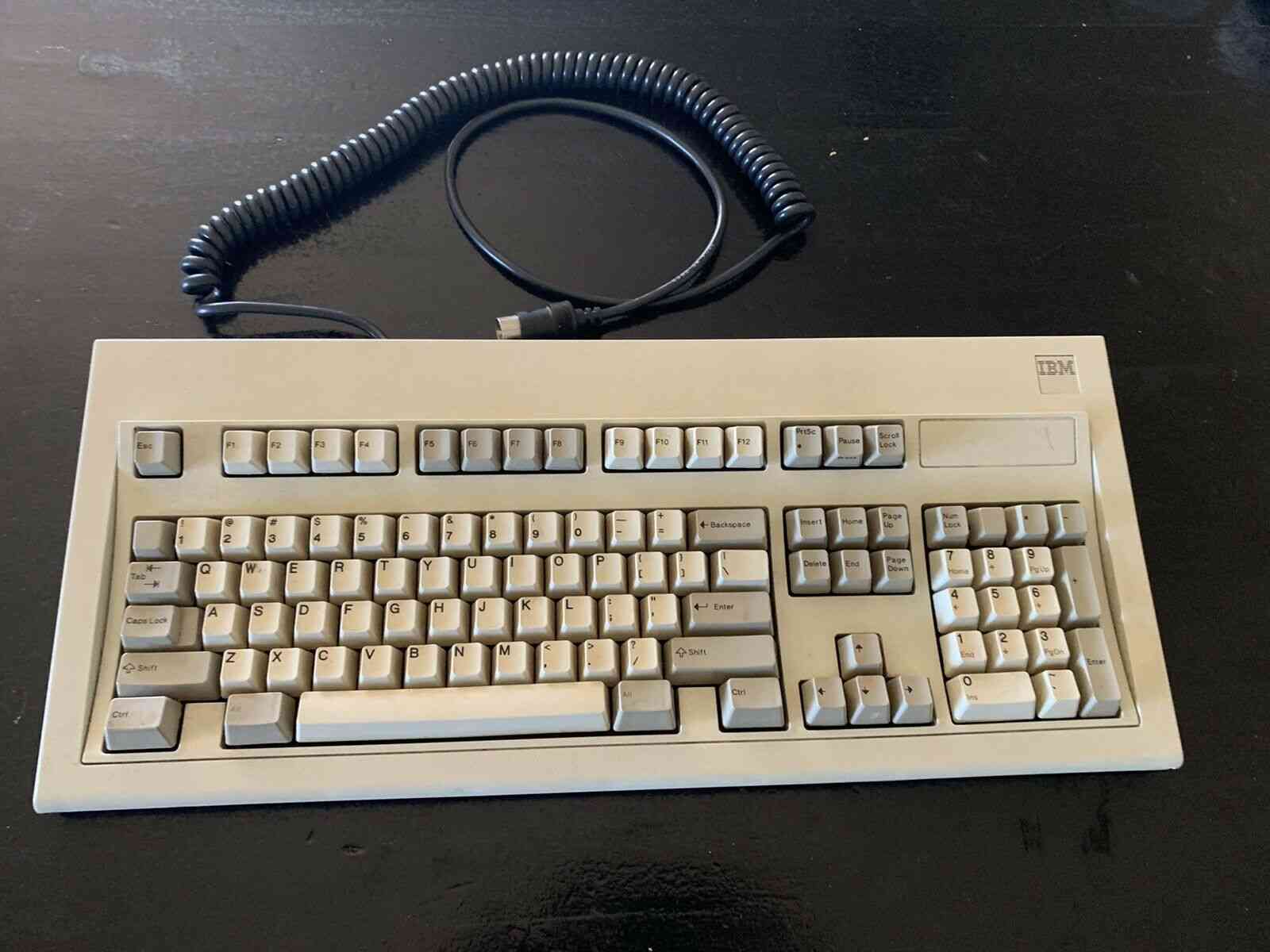

I first purchased an IBM Model M a few months ago, recently I bought another one from ebay. The condition seemed ok visually - some missing key caps and a scratch or two. It is a 1390120 from 1986:

However when I got it, the keyboard felt like typing on a sponge, it obviously needed to have a bolt modification performed on it. This modification involves dismantling the keyboard and replacing plastic rivets holding the membrane together with bolts.

to perform this modification you need a few tools and bolts. Places on the internet will claim you need ~80 M2 2mm machine screws/bolts and ~80 matching M2 nuts and matching washers. This isn't true. I used maybe 20 bolts and nuts, and no washers (even though I ordered them), there just isn't room to put them on.

Another tool you will need is a 5.5mm driver. This is quite a unique driver size, however I happened to have one. Unfortunately though it was too fat to fit into the recessed holes the case bolts are fitted into. So I ended up grinding my 5.5mm driver bit down on a bench grinder.

With the case removed, the damage and dirt can be inspected:

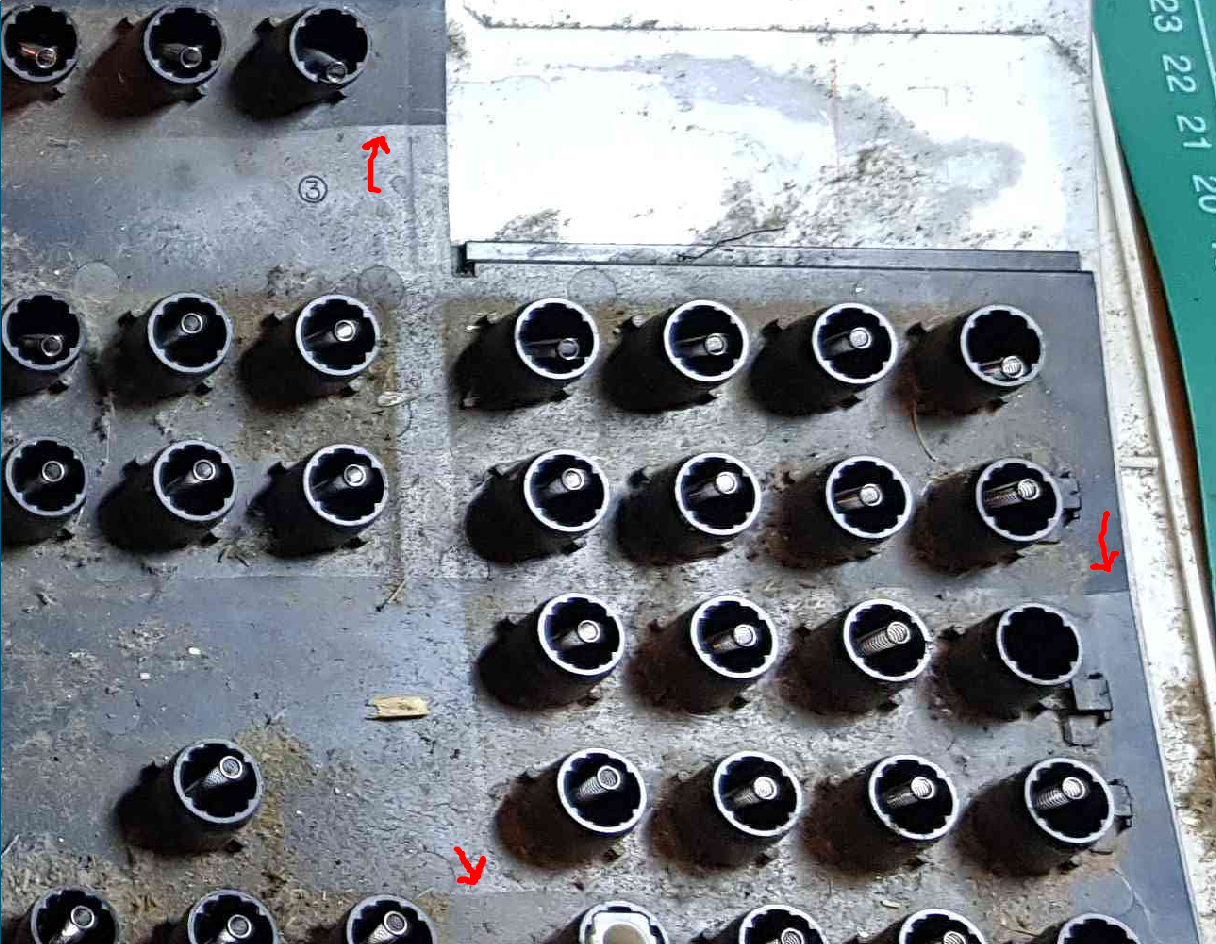

It took me awhile to notice (and for it to snap in half) for me to notice the barrel plate had cracks, and was prone to snapping. (see the arrows) These cracks extend along the whole length of the plate:

I found epoxy resin to be incredibly good for fixing this problem, you can see i glued it back together and filled in the crack on both sides:

I proceeded to clean all the keys, caps, plate, case, sand away the rust etc - that isn't interesting.

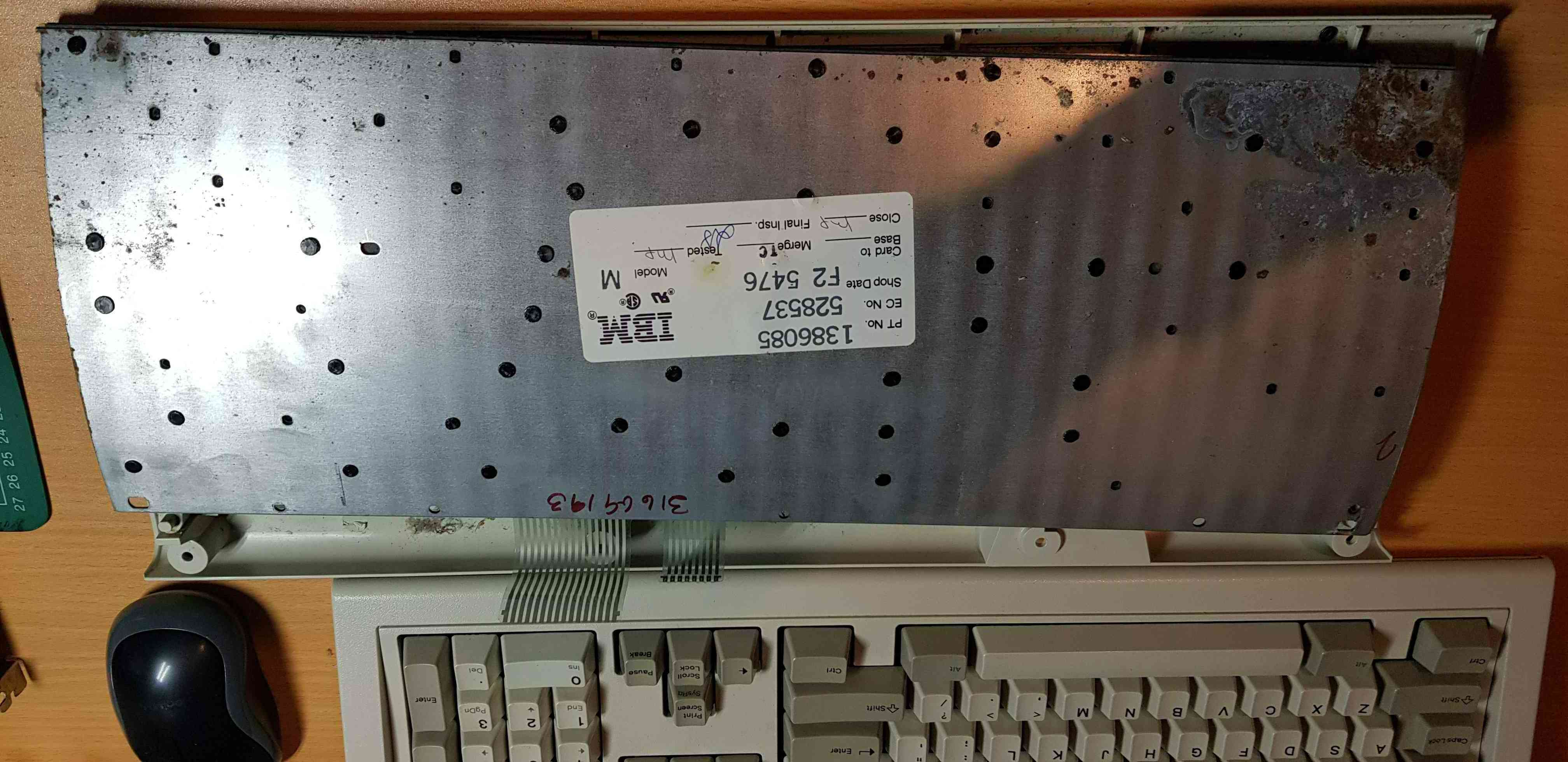

Pictured below the back of the metal plate that holds the key membrane sandwich. The Model M has a major design flaw in that the rivets (the black circles below) used to hold this sandwich together is made of plastic that over time degrades and breaks. It only takes a handful of these to break for the membrane to no longer be held together tight enough for keys to register and feel correct, this is why we replace them with bolts. Mine doesn't look that bad, but it felt bad and did not register keys properly.

I cut off the rest of the rivets using a small craft knife. This let the membrane sandwich come apart into 3 pieces: the barrel plate, a cloth protector and the back metal plate. My model M seems unique as only a few others online have their membrane physically glued to the backplate. It is usually 5 pieces. The posts that were left over by the rivets needed to be cut flat, I did that using nail clippers.

The next step is to drill holes through the barrel plate where the old rivets were located. To do this you use a 1/16" drill bit. To help with the drilling I first marked each post I would have to drill through using some nail polish:

Then, using a soldering iron I don't mind destroying the tip on, I slightly melted through the top of the posts as a guide for the drill bit:

Now I started drilling. This was scary because I thought accuracy was important. It is not, I was sloppy and inaccurate but only a couple holes didn't line up in the end, and like I said, you do not need all rivets replaced. It also makes a mess:

I then reassembled the membrane sandwich, installed the screws and nuts, put it all back together and I had a finished Model M.